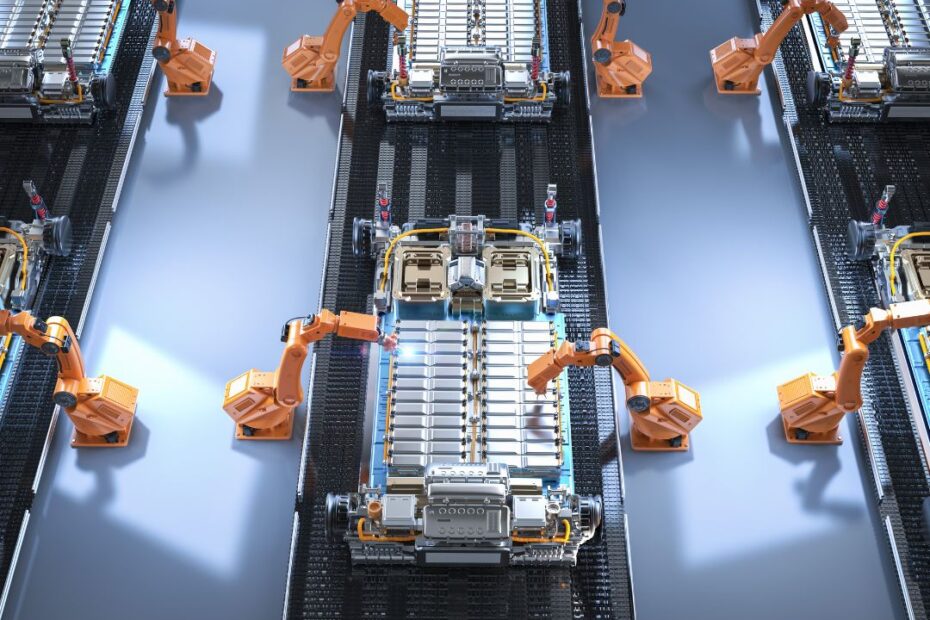

In the fast-evolving landscape of Electric Vehicle (EV) technology, optimizing battery performance is a critical aspect that directly impacts the efficiency and longevity of these vehicles. Today, we delve into the realm of EVs and explore how Programmable Logic Controllers (PLCs) play a pivotal role in monitoring and controlling batteries, ultimately leading to the optimization of their performance.

PLCs: The Backbone of Battery Management Systems for EV

- As EVs become increasingly prevalent, the demand for efficient battery management systems for EV is at an all-time high. PLCs serve as the backbone of these systems, providing a reliable and robust platform for monitoring and controlling various aspects of the battery.

- PLCs are versatile automation devices that excel in real-time control applications. When integrated into battery management systems for EV, PLCs enable precise monitoring of parameters such as voltage, current, temperature, and state of charge. This real-time data empowers engineers and operators to make informed decisions, ensuring optimal performance and safety of the EV batteries.

- Implementing PLCs for battery management systems for EV aligns seamlessly with the benefits of Robotic Process Automation (RPA). The automated monitoring and control processes provided by PLCs not only enhance accuracy but also reduce the risk of human error, leading to increased operational efficiency and improved battery performance.

- Beyond the realm of EVs, PLCs have been at the forefront of revolutionizing factory automation. The same principles of real-time control and monitoring apply, making PLC control panels an integral part of optimizing EV battery performance. The adaptability of PLCs ensures they can seamlessly integrate into diverse manufacturing environments, providing a standardized and efficient solution. Additionally, PLC control panels streamline maintenance procedures, enabling quick diagnostics and troubleshooting to minimize downtime and maximize uptime. As manufacturing evolves and adapts to new technologies and market demands, PLCs remain a constant, reliable backbone, driving innovation and efficiency in factory automation beyond the scope of electric vehicles.

- Just as LabVIEW software is driving innovation in pharmaceutical automation, the integration of PLCs inbattery management systems for EVs is propelling advancements in the electric vehicle industry. LabVIEW’s capabilities extend beyond pharmaceuticals, and in the context of EV battery optimization, it can be employed to enhance the visualization and analysis of PLC-generated data, offering a comprehensive solution.

- Supervisory Control and Data Acquisition (SCADA) systems further augment the capabilities of PLCs battery management systems for EVs. SCADA provides a centralized platform for visualizing and managing the vast amount of data generated by PLCs. This enhances the overall efficiency of battery management systems for EV by providing real-time insights, enabling proactive decision-making, and facilitating remote monitoring. Moreover, SCADA systems offer advanced analytics capabilities, allowing for in-depth analysis of battery performance trends and predictive maintenance. By leveraging historical data and machine learning algorithms, SCADA systems can anticipate potential issues before they occur, optimizing EV battery performance and extending battery life.

In conclusion, the optimization of EV battery performance is a critical aspect of advancing the electric vehicle industry. At Puja Controls, our expertise in providing customized digital test equipment extends to the realm of EV battery management. By harnessing the power of PLCs, we contribute to the efficiency, safety, and longevity of electric vehicle batteries. As technology continues to evolve, the synergy between PLCs, SCADA industrial automation, and other cutting-edge solutions will play a crucial role in shaping the future of electric mobility.

In addition to our commitment to advancing EV battery performance, Puja Controls remains dedicated to staying at the forefront of technological innovation. We continuously strive to expand our expertise and offerings to meet the evolving needs of the electric vehicle industry. From developing state-of-the-art testing methodologies to integrating emerging technologies like AI and IoT, we are poised to lead the charge in driving efficiency, safety, and sustainability in electric mobility. Together, let’s pave the way for a greener and more efficient future of transportation.

Pingback: LabVIEW Software: The Future of Pharmaceutical Automation - LabVIEW Software Experts for PLC System Integration and Poka Yoke Tools

Comments are closed.